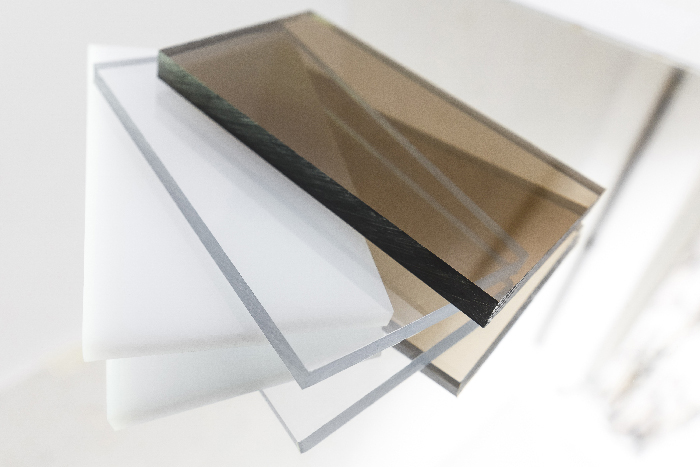

Much like the material you use, the variety of the material, whether in terms of color or thickness, has its own advantages and disadvantages. Acrylic panels, with a variety of colors and thicknesses ranging from 1.5 mm to 18mm, are a perfect example of such. Acrylic can be used in different applications, but what is the right thickness to use for your specific project? Listed below are some scenarios with the appropriate acrylic thickness to use:

For signages:

If you want a customized build up signage, that’s also lightweight and durable, use acrylic panels. Acrylic signages can be in the form of individual cut acrylic letters, or laser-cut acrylic logo signs. Generally, 2 to 3 mm acrylic thickness is enough for a regular signage.

For curved applications:

Technically, all varieties of acrylic can be bent, provided that there is ample heat and time allotted for the material. However, some techniques can make the final look to be imperfect and not as seamless as you expect it to be. For best results, 3mm to 6 mm acrylic can be used.

For a person to walk on:

It is not recommended to walk on acrylic panels especially if they were used as a roofing material because it is slippery. But if necessary, it is still best to walk on the frame support and not directly on the sheet. If you are using acrylic as transparent roofing, then it is recommended to use at least 6 mm especially in a high altitude area, as precaution against strong winds. Just make sure that proper framing is implemented, to accurately provide support for the acrylic.

For glass replacement:

Acrylic is a great choice for a material that is not prone to breakage and is workable. This is the reason why acrylic is commonly used in commercial areas, used as acrylic barriers and holders on sale displays. If you plan on replacing glass with acrylic, it is best to measure the existing structure and match it with the sheet you are planning to buy.

For DIY projects:

For applications that have the general purpose of carrying or supporting other things, such as shelves or tables, a thicker acrylic should be used. Think about the weight of the objects you will place on it, as well as the support underneath. To ensure stability of the material, it is necessary to use a thicker acrylic like 8mm to 10mm. If you want to create a DIY aquarium using acrylic, you may want to consider using at least 10 mm sheet to keep it together. The thicker acrylic, the rigid it is. It is also important to use thicker acrylic if your DIY project is placed in high traffic areas.

The thicker the material, the higher the price of the acrylic sheet. Considering this, you might be thinking, “Is the cost worth it?” and “Does acrylic thickness really matter?” The easy answer is yes. The thickness of the acrylic affects more than you think. While acrylic itself is a robust material, supports are still needed to make it last longer. A stronger acrylic also keeps it from being easily broken. If you want to make sure you get the right thickness for your project, you can look for an acrylic thickness calculator online or consult with a professional and your Philippine acrylic supplier. Contact Acrybest for more information.