You might come to see a laser cutting video on your timeline tagged under the hashtag satisfying videos, and rightfully, it is. While the process seems to be complicated, the technicality behind it is actually easier to explain. Laser cutting is a production process under the Computer Numerical Controlled (CNC) machine, which uses a computer to direct the beam and dictate the design loaded onto the machine.

What is the process behind laser cutting?

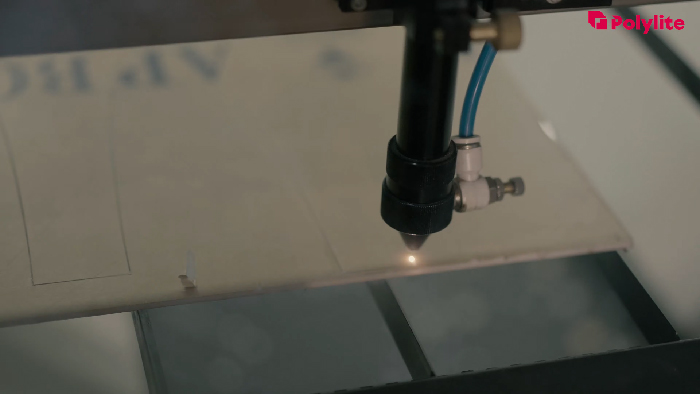

Laser cutting is a noncontact process that uses a laser cutter beam to cut through the material. The laser penetrates through by burning, melting, and vaporizing the edges. Think of any regular printer. First, you lay out the design on a software program before printing. The same thing works with a laser cutter. Once design is loaded to the machine, the machine operator automates it, and then allows the laser beam to move over the material to cut until the pattern is completed. Depending on the material used and its thickness, the power can be adjusted.

Pros of laser cutting

- Seamless- Laser cutting ensures accuracy and high level of precision compared to other cutting methods. It can cut through complex designs with a seamless finish, and create replicas with the same exact copy of another.

- Faster and Easier Production- The overall process of laser cutting is easy since it does not need actual manual labor to do the work. Through the use of laser cutting machinery, an experienced machine operator can input the data and wait for the machine to do the work.

- Low Risk of Damage- The use of a laser cutting machine reduces the risk of damage for both the material and the beam. Since it is noncontact, there is less friction and pressure that makes the tool wear down. It cannot be deformed nor be contaminated. Moreover, it keeps the raw material intact even after cutting complex designs.

- Adaptability- Laser cutting is used in different raw materials regardless of its composition, thickness, and shape. It can be used even in the most intricate designs; you need not to replace the beam to adapt.

- Widely used in Various Industries- A lot of the materials we use in our daily lives have gone through a cutting process in one way or another. For construction, electronics, automotive, and medical industries, which require absolute precision to meet their requirements, laser cutting is recommended.

Cons of laser cutting

- High power consumption- Depending on the material, it may consume a lot of energy.

- Upfront Cost- The laser cutting machine itself can be costly and will cost twice as much as other cutters.

- Requires professional automation- Although the process is easy, the operator must still be knowledgeable about how it works to prevent mishaps and other accidents.

- Limitations- Like any other material, it has its limitations. it cannot cut through thicker metals.

- Environmental Concerns- The process of laser cutting includes melting and vaporizing different kinds of raw materials which may emit hazardous fumes that harms the environment.

One of the materials which uses laser cutting is acrylic panels. More than the seamless finish, the laser cutting machine is used on custom signages and other client requirements because it makes the process easier and faster compared to other tools. Find out more about the process of cutting acrylic sheets by watching this video . Acrybest is a trusted brand of acrylic glass in Manila, known for its acrylic products and services, including build up signages, custom displays, and regular signages. The acrylic sheet prices are available on site so you can easily access it along with its application by clicking here. For more information about acrylic and where to buy it, you may contact Acrybest, one of the trusted acrylic suppliers in the Philippines.